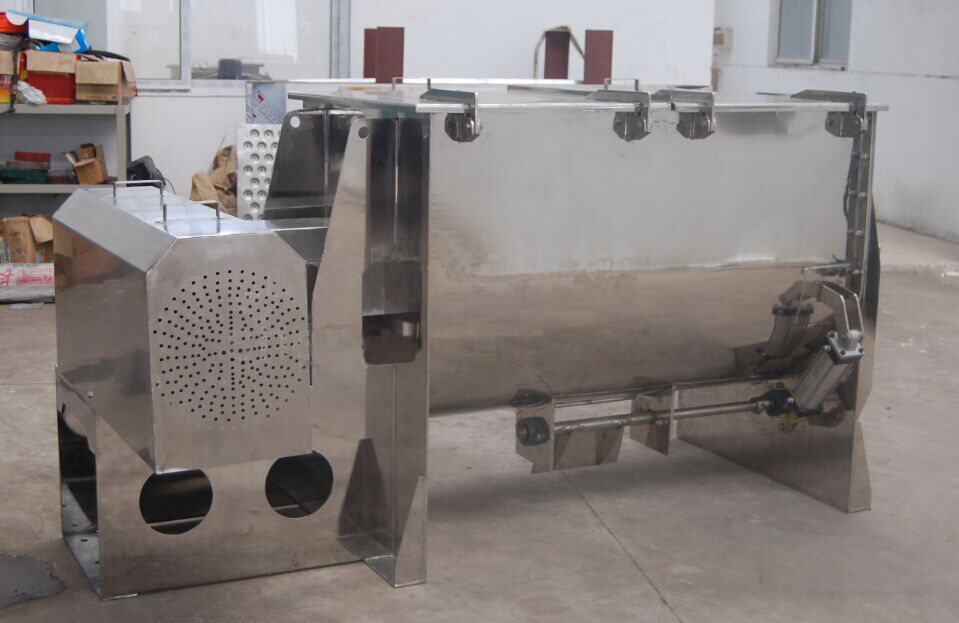

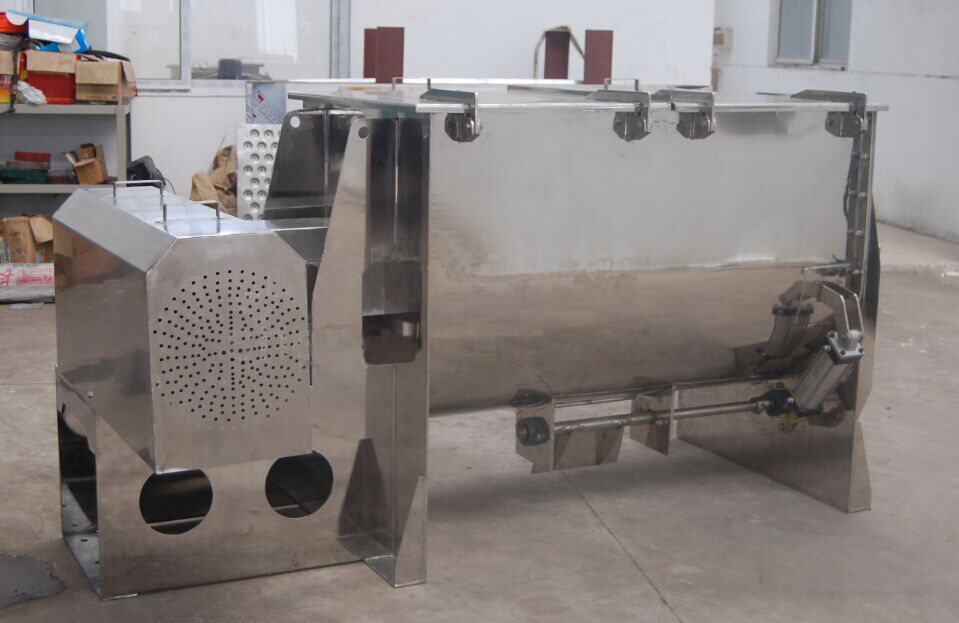

WLDH-500 Horizontal Type Ribbon Mixing Machine

Product Description

Simple Description

Horizontal ribbon mixer, also known as ribbon mixer. The barrel of the mixer has a U-shaped long structure, which ensures the small resistance movement of the mixed material (powder, semi-fluid) in the barrel. Double-layer spiral blades are arranged on the transmission main shaft, the inner spiral belt conveys the material to the outside, and the outer spiral belt gathers the material to the inside. The material forms a low-power and high-efficiency mixing environment under the convective movement of the double-layer spiral belt. The inner and outer diameter spirals installed on the mixing shaft drive the material in the barrel, so that the agitator can turn the material in the largest range in the barrel. When the mixing device is working, the inner spiral drives the material near the axis to make the axis rotation, and the axial direction is pushed from the inside to the two sides, and the outer spiral drives the material close to the barrel wall to make the axis rotation, and the axial direction is pushed from both sides to the inner. It can be uniformly mixed in a short time. Bottom discharging method: the powder material adopts the pneumatic large-opening structure, which has the advantages of fast unloading and no residue; high-fineness materials or semi-fluid materials adopt manual butterfly valves or pneumatic butterfly valves, manual butterfly valves are economical and applicable, pneumatic butterfly valves are half-half The fluid tightness is good, but the cost is higher than manual butterfly valve. Where heating or cooling is required, a jacket can be configured. There are two heating methods: electric heating and heat-conducting oil heating: electric heating is convenient, but the heating speed is slow, and the energy consumption is high; the heating of the heat-conducting oil requires an oil pan, oil-conducting power, and pipelines, and the investment is large, but the heating speed is fast , Low energy consumption. The cooling process can directly inject cooling water into the jacket. The jacket has a large heat exchange area and a fast cooling rate. The motor and the mixing spindle are directly connected through a cycloid pinwheel reducer, which has a simple structure, high operating reliability and convenient maintenance. .

Application

The ribbon mixer is widely used in putty paste, real stone paint, dry powder, putty, medicine, food, chemicals, feed, ceramics, refractory materials, solid-solid (namely powder and powder), solid-slurry (namely powder It is especially suitable for the mixing of viscous materials. This mixer is not suitable for mixing materials with large fiber content and large density differences. It is recommended to use stainless steel ribbon mixer for putty paste, real stone paint, biology, medicine, food and other industries. Horizontal spiral ribbon mixer is used in pesticides, veterinary drugs, food, chemicals, biology, aquaculture, ceramics, refractory materials, plastics, compound fertilizers, etc. It is also especially suitable for mixing viscous materials. To The horizontal ribbon mixer is composed of a U-shaped container, ribbon mixing blades and transmission parts; the positive and negative rotating ribbons are installed on the same horizontal axis to form a low-power and efficient mixing environment. The ribbon-shaped blades are generally made of double layers. Or three layers, the outer spiral gathers the materials from both sides to the center, and the inner spiral conveys the materials from the center to the two sides, which can make the materials form more eddy currents in the flow, speed up the mixing speed, and improve the uniformity of mixing. ; The belt pulley is used to drive the cycloid reducer. Compared with the large torque of the gear reducer, the elastic connection of the belt drive has the advantage of protecting the transmission parts when overloaded. The discharge form of the horizontal ribbon mixer is generally a pneumatic (manual) flap valve. The arc valve is tightly embedded in the barrel and is flush with the inner wall of the barrel. There is no material accumulation and mixing dead angle phenomenon. The reliable side strip seal ensures that the There is no leakage during frequent switching; the machine can add a jacket outside the mixer barrel according to the process requirements, and cool or heat the material by injecting cold and hot media into the jacket. When mixing ultra-fine powder, the main shaft is sealed The form can increase the airtight setting, effectively blocking the flow of air and powder inside and outside the cylinder.

Main Technical Data

Type | Full volume (M³) | Loading factor | Motor Power (KW) | Size(mm) Length*width*height | Weight(kg) |

WLDH-500 | 0.5 | 0.4-0.6 | 7.5 | 2730×700×1700 | 980 |

Details Images

Company Profile

Q: What price terms you offer? A: We can offer FOB, FCA, CFR, CIF, EXW and other price terms based on your request. Q: What payment terms you take? A: TT, LC, other terms are also workable. Q: Will you help with installation and stuff training? A: Yes, we can send our engineers to your place to guide the installation and train your workers if you need, but the buyer should bear our technician's round tickets, accomodation, food and subsidiary USD100/day. Q: How can I visit your factory? A: Our factory is located in Ruian city Zhejiang Province. Just let us know your scheduel in advance and we will arrange everything for you! Any other doubts about our machine, please feel easy to contact with us.

Product Categories : Solid Workshop Preparation Equipment > Mixing Machine

Premium Related Products

Other Products

Hot Products

Fertilizer Pelletizer / Fertilizer Making Machine / Fertilizer Granulator (DP)China Lowest Price Hot Sale Fertilizer Disc Granulator MachineHigh Uniformity Mini Price Fertilizer Granulator MachineMini granulator extruder machine/pellet machineMini granulator extruder machine/pellet plantMini granulator extruder machine/fertilizer production lineMini granulator extruder machine/granulating lineXSG Series Rotary Flash DrierXSG Spin Flash Drying EquipmentGMC Series High Pressure Pulse Bag Type Dust CollectorJRM-I Series Burning Coal Hot blast furnaceCompound fertilizer granulating compactor/pellet millNPK Fertilizer Granulator Machinery in China factoryFertilizer Double Roller Briquette MachinePellet MillNPK Fertilizer Granulator Machinery in China factory