LTRZ-10 Pharmaceutical Automatic Vacuum Mixing Emulsifier Homogenizer for Cosmetic Cream milk

Product Description

LTRZ-10 Vacuum Emulsifier Mixer—PLC Control

LTRZ-10 Vacuum Emulsifier Mixer

Includes:

1.Contact parts with stainless steel 316

2.Oil pot

3.Water pot

4.Button Control

Working principle:

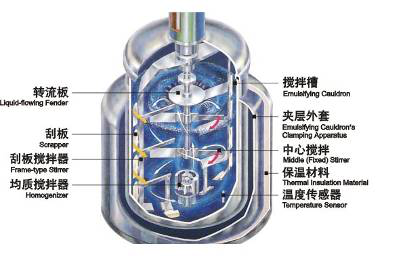

The LTRZ-10 Vacuum Emulsifying Mixer is composed of main pot(emulsifying pot),a water phase pot and an oil phase pot, vacuum unit, up-and down system, electrical control system and the motor frame etc.

The main pot is composed of the cut-off mixing pot, cut-off mixer unit, circulating system and the stirring system etc.

The materials are sucked into emulsifying pot by transportation pipe under the vacuum state, or it also can be put from the feed inlet.

The material are stirred by both the center blade and side scraper, which works on the inner surface of pot keeping stirring materials from being stuck onto the wall. In the process of blade-stirring, the materials are continuously crushed, pressed, fold. Then the material is sent to the cut-off mixing unit where they are again cut off, broken and stirring by the strong interaction between running cutting wheel and cutting sheath. The materials are finally crushed into small pellets of 200um~2um. Besides, because of the vacuum in emulsifying pot, the bubbles generated during stirring and mixing process are sucked out from material. The ex-circulating system can make the homogenizing more strong. The material within the pot can be give off only under the state of change direction of the control valves.

The temp controller on operation panel can adjust the temp of the homogenizer pot; The homogenizer stirring and the blade stirring cab be used simultaneously or dividedly; The homogenizer stirring time can be set by the custom according to the different material. After finished the whole procession please rise the pot cover for the clearing.

Main Technical Data:

Manufacturer | China LTPM Group Co., LTD | ||

PN | 10L vacuum emulsifying mixer | ||

Capacity | Design volume: 12L, working capacity:10 L | ||

Kettle Cover | Liquid(particle)inlet, sunk material inlet, air inlet with filter, inspect light and sight glass, vacuum port, pressure meter(1 to -0.1 bar), pressure clamp | ||

Mixing pot |

Material | Inner layer: SUS316L thickness: 3mm | |

Middle layer: SUS304 thickness: 2mm | |||

Outside layer: SUS304 thickness:2mm | |||

configuration | Bottom material exhaust, size: 1.5” | ||

Temp. sensor (0-199℃) | |||

Electrical heating: 2kw, cooling water inlet | |||

Stirring system |

Homogenizer | 1.Material: SUS316L; standard homogenizer 2. Power: 0.18 kw/380/50Hz; RPM: 0--2800R/Min | |

Stirring scrap and middle stirring | Material: SUS316L,Scrap material: PTFE | ||

1. Stirring scrap and middle stirring use the same motor 2,Power:0.1 kw/380V/50Hz;RPM:50r/min(Frequency control) 3. Stirring scrap and middle stirring rotating the opposite direction | |||

Safety: 1. During stirring, the cover can not open, 2. Cover lift can not stirring. | |||

Vacuum system | 1. Vacuum pump: water recycle, power 0.37kw/380V/50Hz 2. With pressure sensor (during vacuum condition, hydraulic can not open) | ||

Heating method | Jacket electrical heating | ||

Exhaust method | Electric doom and bottom discharge or positive pressure discharge material | ||

Pressure | Pressure in the pot during working: -0.090 Mpa; Jacket working pressure:0.2 Mpa | ||

Control box | SUS304 , 1.2mm thickness | ||

Dimension | 1400mm×600mm×1900~2400 mm | ||

Shelf is SS, platform with raised platform and SS guardrail | |||

Spare parts | One year spare parts and tools | ||

Guarantee | One year | ||

Using life | More than 15 years | ||

Remarks:

1. Contact products material is SUS316L, surface polish. Others SUS304, surface polish. Sealing material is VITON, scrap material PTFE, pipe line connection use TRI-CLAMP, easy for take out. Motor with SS cover for protection.

2. Welding: all welding parts are full weld.

Pictures of Products:

Our Services:

Installation and after sales service:

Installing and Commission: We will install and test the machine in best working condition before shipment. If customer requires our technician to adjusting the machine and train technician at arrival place, we will send technician there. All our expenses including round-trip air ticket to the nearest airport, local conveyance to your factory, Lodging & Boarding expenses shall be payable by you. In case the stay of our technician, the service charges US $ 50 per day will be charged extra.

Warranty Period:

There is one year for fully machine guarantee. And in this year if the machine broken caused by Mechanical problem, all of the spare part is free. The service of the machine all though the machine’s life.

After sales service:

1.We have seven technicians who gets passport ready to travel all over world to offer service to you.

2.We have 24 hours hot line for technical support.

3.We get 18 hours internet line for technical support.

4.Video camera in workshop to help you adjust and solve machine problem in working situation.

Company Information(Certificates):

If you are interested in our products or want more details, please feel free to contact us. Thanks!

Product Categories : Emulsifier

Premium Related Products